Glass is one of the most widely used components in modern architecture. It’s also a popular material in daily-use items like tableware, mirrors, packaging, vehicles, and light bulbs. But when glass is involved—regardless of the application—safety is paramount. As glass can be sharp and dangerous upon breakage, it’s important to adhere to some universal glass safety standards when working with it.

In this post, we’ll discuss the glass safety standards to help you ensure compliance the next time you work with the material.

Understanding Glass Safety Standards

When glass breaks or shatters, it can form sharp pieces, which may lead to bodily harm. Lacerations, nerve damage, and tendon damage are all common injuries associated with glass breakage, injuries that underscore the importance of adhering to glass safety standards. Simply put, glass safety standards offer information on safety relevant to impact resistance, shatter protection, and the material’s overall durability.

Glass safety standards are regulated by reputable organizations. In the United States, they’re regulated by the American National Standards Institute. In Europe, such standards are regulated by the European Committee for Standardization.

Types of Safety Glass

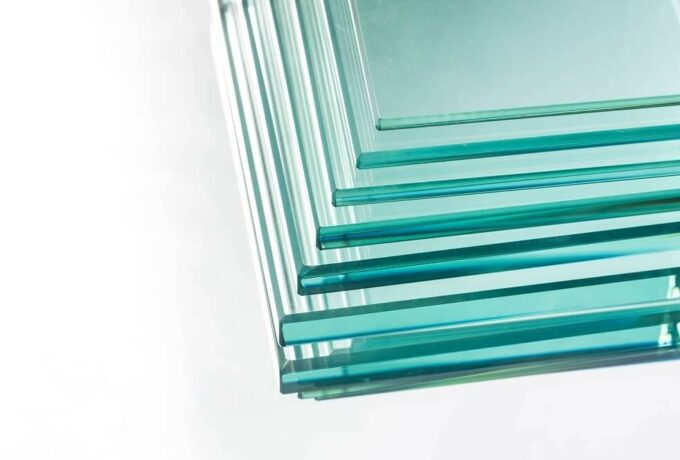

The term “safety glass” is fairly broadly used, but there are different sub-types of this type of glass. They are:

- Tempered: You’ll often find tempered glass in residential and commercial settings and applications. This glass is heat-treated and designed to be very durable – up to four times as strong as conventionally made glass.

- Laminated: A more durable and safer type of glass compared to tempered glass, laminated glass consists of two pieces that are bonded together to create one strong, uniform layer. In addition to being strong, laminated glass offers better resistance to sound and UV rays. It’s often used in commercial buildings, to create glass floors and more.

- Reinforced: Reinforced glass is a strong type of glass that’s often used to enhance home or property security at points of entry, like doors and windows. Some types can even withstand explosions. It’s created using high heat and then rapidly cooled.

Key Safety Standards for Glass

Several safety standards apply to glass products. Some of the factors involved include:

- Impact resistance: Impact resistance measures how much force a type of glass can withstand before it’s damaged.

- Thermal stress: This measures the performance of the glass over a specified temperature range.

- Breakage characteristics: Does glass break into sharp edges, small particles, or something else? That’s what breakage characteristics help to determine.

All glass is tested to meet industry standards. It’s tested visually for temperature and for impact resistance to determine if it meets quality standards and can withstand various types of environmental exposure.

Importance of Compliance

Compliance with glass safety standards is everything. Failure to comply with designated standards leaves manufacturers subject to legal implications. Beyond this, it also subjects people to injury and bodily harm if the glass doesn’t meet certain quality standards for the application it’s being installed in.

How to Verify Compliance

There are a variety of ways to ensure glass products meet or exceed designated safety standards. Perhaps the best way is to only work with reputable manufacturers that produce high-quality materials. Other ways to verify compliance include looking for certification markings (i.e., Tempering Standards, Safety Certifications, etc.) that indicate standards have been met and visually inspected for uniformity and color consistency. Only glass that meets specific safety criteria should be used according to the application.

Contact Us Today

For more information on glass safety standards, visit the Insulating Glass Certification Council, Safety Glazing Certification Council, ANSI, or another governing body of glass safety standards. If you want to work with a reputable glass manufacturer, contact us at AMG today for all your needs, regardless of your application. We’re standing by and ready to meet your next application’s glass needs and safety requirements.